On the metal and women’s fate

- 27.05.2022

- News-Eng

- Comments Off on On the metal and women’s fate

- sdauren

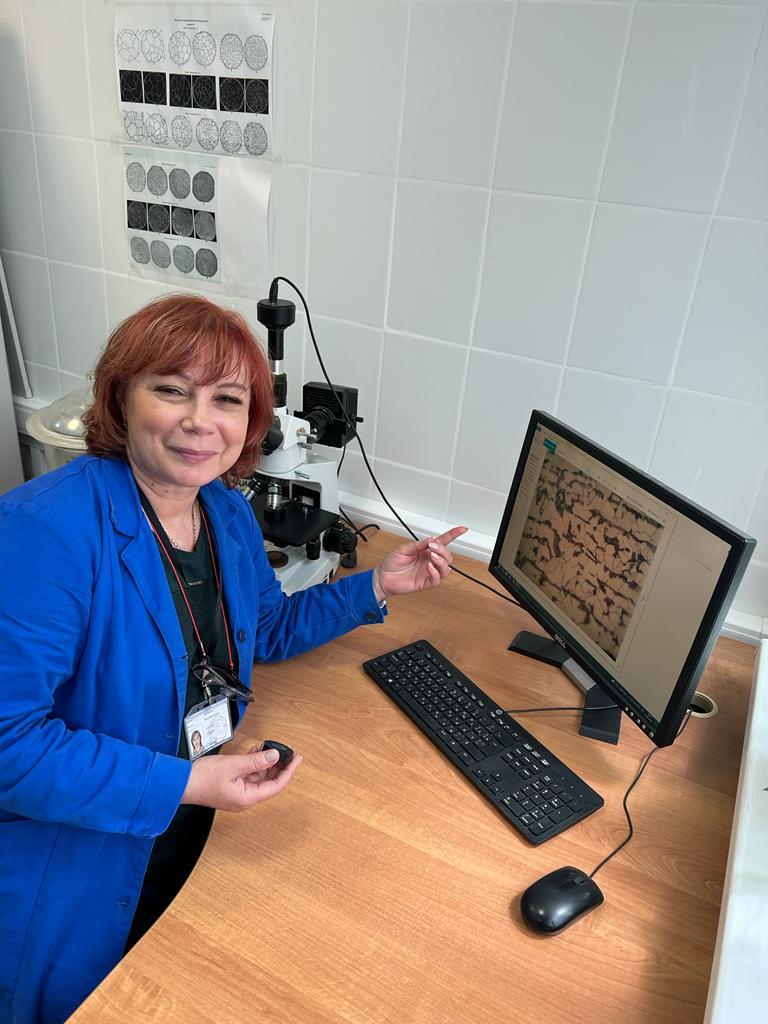

For the third year in a row, a metal research laboratory has been successfully operating at the “KazNIPImunaigas” Branch of KMG Engineering LLP. Few people know that this new sector in the activities of the institute is managed by a lady with extensive experience in the brutal metallurgical and energy industries, a native of Siberia, Svetlana MARCHENKOVA. Information about the laboratory, interesting professional biography and young personnel of KazNIPImunaigas are set out in this material.

In April 2019, in accordance with the order of the General Director of KMG Engineering B. Khasanov, a new laboratory for a metal research has begun to function at the KazNIPImunaigas Branch of KMG Engineering LLP. The decision to launch a new sector in the activities of the institute was made in connection with the need to determine the causes of premature failure of metal structures in the fields and the possibility of using new materials to extend the life of surface and downhole pumping equipment for subsoil users.

Today, the laboratory in Aktau is equipped with high-tech equipment for metal testing, research and analysis, which makes it possible, among other things, to identify low-quality products at the stage of incoming inspection, to determine the compliance of the brand with national and international standards, technical specifications of product manufacturers. In case of failure of metal products, it is possible to study the causes of metal destruction and issue recommendations within their competence. Today, the customers that use laboratory services are the largest subsoil users of Mangistau, Atyrau, Aktobe and Kyzylorda regions.

For me the metal – vital!

“The goal of our work is the reliable and safe operation of oilfield pipes, pumping rods and any other critical metal structures says Svetlana MARCHENKOVA, Head of the laboratory for the SAF metal research of the Department for laboratory research of the KazNIPImunaigas Branch of KMG Engineering LLP. Svetlana Evgenievna has worked in the field of metal science and mechanical testing of metal for 32 years. She began her career in 1990 in the metal laboratory of the Mangyshlak Nuclear Power Plant (MAEK), researching metal during incoming inspection and determining the causes of accidental destruction of power equipment elements. Later she has managed the production testing laboratory of the plant for the production of large-diameter spiral-seam pipes and the application of a protective coating at ArcelorMittal Tubular Products Aktau JSC. The main activity of the laboratory was to test, research and analyze the metal of pipes of our own production and production of other manufacturers of pipe products for oil national and foreign companies. – I got into the industry by accident. Having studied during evening time at the Tomsk Polytechnic Institute in the Faculty of Chemistry and Technology during evening time, I realized that chemistry is not what I want, so the next year, based on the advice of a friend, I went to apply to the same institute, but to the Faculty of Engineering, specializing in powder metallurgy and sprayed coatings. I successfully entered the specialty and graduated from the university in 1990 with the qualification of a metallurgical engineer. Returning to native city Aktau, she faced difficulty finding a job. I applied to many laboratories that matched my qualifications, but everywhere they were hiring for only male workers. Once my mother was driven to work by her friend, who ran the metal laboratory at the Mangyshlak nuclear power plant MAEK. At first, he also sharply cut off that he would categorically not hire a female worker. But after my mother’s upset remark, when he heard that I had studied for a metallurgist, he promised to help with employment at his laboratory. So this way metal came into my life! I worked at MAEK for 22 years: for the first 5 years as a laboratory assistant-metalographer of the 7th category, then as a metallographic engineer. I liked the work. In addition to the control of metals and welded joints by destructive methods, I was engaged in research into the causes of destruction of elements of power equipment, conducting a set of mechanical tests and metallographic studies. In 2012, I was invited to work in a foreign company ArcelorMittal Tubular Products Aktau JSC as the Head of the production testing laboratory. The laboratory was ultra-modern, with the latest unique equipment. I had to retrain quite in metal research, here metal products of the oil and gas industry are tested and investigated. But metal is metal. For me, it is vital! It is like a human, is born, lives and works, ages and dies. While working at ArcelorMittal, I met a large number of subsoil users in our region. For me, these contacts were very useful and fruitful. Many specialists referred to our laboratory, including workers from the Branch of KMG Engineering LLP. KazNIPImunaigas. They enthusiastically talked about the behavior of metal in an aggressive environment, asked questions about the properties of the metal, and I, in turn, was happy to share information. I believe that at that time they “probed” me as a specialist and, apparently, having convinced themselves of my competence, after a while they invited me to work at the institute. I was happy because I dreamed of doing science. On June 10, 2019, she started working as the head of the metal research laboratory of KazNIPImunaigas” S. Marchenkova shared her story.

A secure future for the new laboratory Today, the Metal Research Laboratory employs a small but friendly team of highly qualified specialists. A native of Temirtau, Kamila Turgunova graduated with honors from Karaganda State Industrial University in 2008 with a bachelor’s degree, and in 2017 also with honors from Karaganda State Technical University with a master’s degree in technical sciences.

Camila has ten years of experience in the metallurgical and machine-building industries, in which the main functional areas are quality control of manufactured metallurgical products at all stages of production and quality control of welded metal products. From 2016 to 2019 worked in the oil and gas sector at the projects of the Tengiz field, at the same time I was engaged in scientific activities in projects for iron ore pelletizing of charge materials intended for blast-furnace smelting on the basis of Karaganda State Technical University and ArcelorMittal Temirtau JSC. In the course of these works, a laboratory plant for pelletizing was designed, and eight scientific articles were published, two of which are included in the Scopus database. Today, Kamila, together with her leader Svetlana Evgenievna, is part of the project team of the Competence Center to combat complications in oil production. The main area of work in this group is the selection of metal for downhole pumping equipment for the fields of JSC NC KazMunayGas. Last year, the outstaffing sector engineer Turkmenbay Daulet, who has a Bachelor of Engineering and Technology degree in Chemical Technology of Organic Substances, joined the subsidiary company. According to colleagues, with his arrival to the board, mountains of metal fell from the girl’s shoulders. Now he is successfully mastering a new profession, specializing in sample preparation for testing and research and learning how to work on new equipment.

– I am happy that a team works with me shoulder to shoulder. We all complement each other, support each other, and find ways out of the most difficult situations. Now I know for sure that not only men can work with metal. Our field of activity is expanding every year, so we are waiting for specialists of our rare, as of today in our region, profession, – Svetlana summed up.